Starter Solenoid Strip and Rebuild

I pulled my starter solenoid off because it appeared to be sticking. The symptoms were that when the key was turned to the cranking position, the fuel pump would fire up but apart from a click from the starter relay, the starter motor would do nothing. OK, there are various other potential causes (dead relay being one, bad earth being another) but what I found was that if I kept the key turned for some indeterminate period, eventually the motor would kick in and start the car... so it looked likely that the solenoid was 'creeping' rather than pulling-in hard as it should.

So, to work. Disconnect battery, jack up car, take off driver's side front wheel. The starter lurks behind the exhaust downpipes at the rear of the wheelarch. The solenoid is held to the motor by two small screws that require an 8mm spanner and the arms of Stretch Armstrong to undo. They're not tight, just about as accessible to the average man-sized hand as Emma Bunton's knicker drawer. I found that I had to lie under the sump and feed my arm up between the gearbox and exhaust to get at the screws... but before you rush in, first you need to disconnect the battery cable, the motor cable and the cranking wire from the solenoid. The cranking wire pulls off; the other two need sockets or spanners to remove. They are fractionally easier to access than the solenoid retaining screws. With the wiring detached and the screws removed, the solenoid can be wriggled forward and pulled off its armature, which will stay attached to the starter (note the Hex bit in case I needed to take the whole starter off!):

You should be able to move the armature forwards and backwards a small amount quite easily; if it's stiff then the Bendix drive is probably sticking on the starter motor shaft - and that in itself could be the reason the motor refuses to pull in.

Remove the solenoid to the workbench/ kitchen table (delete as appropriate):

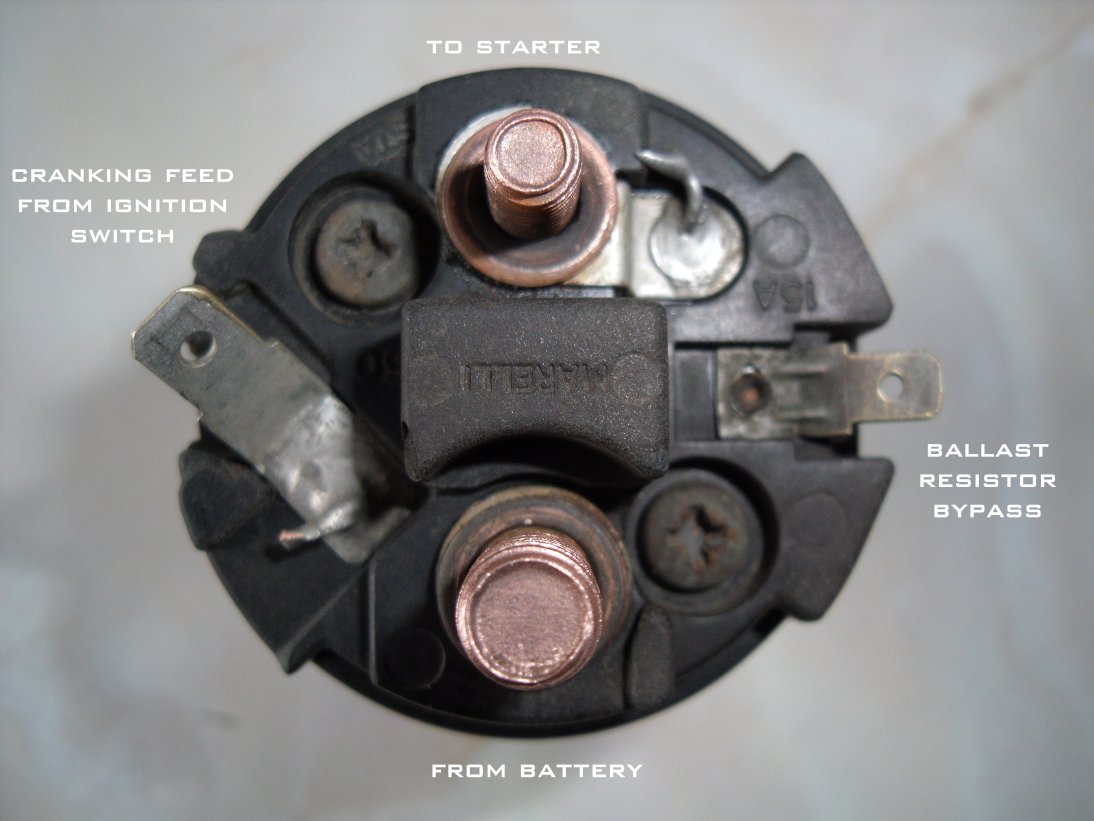

The various connections to the solenoid are as follows:

The ballast resistor bypass connection might not be used, although I think some versions of the RV8 did have a ballast so there could be a connection here. You shouldn't get it and the cranking feed mixed up as the terminals are clearly different sizes.

To dismantle the solenoid you first need to desolder the two connections to the internal copper windings:

A desolder sucker will help, or you can use the old heat'n'shake method.

With the solder removed, use a pair of pliers to straighten the wire ends so that they'll pass cleanly through the terminals:

Next, press firmly downwards on the end cap whilst you remove the two retaining screws (there's an internal spring that will try to push the cap off):

Carefully lift the end cap away and you will reveal the workings:

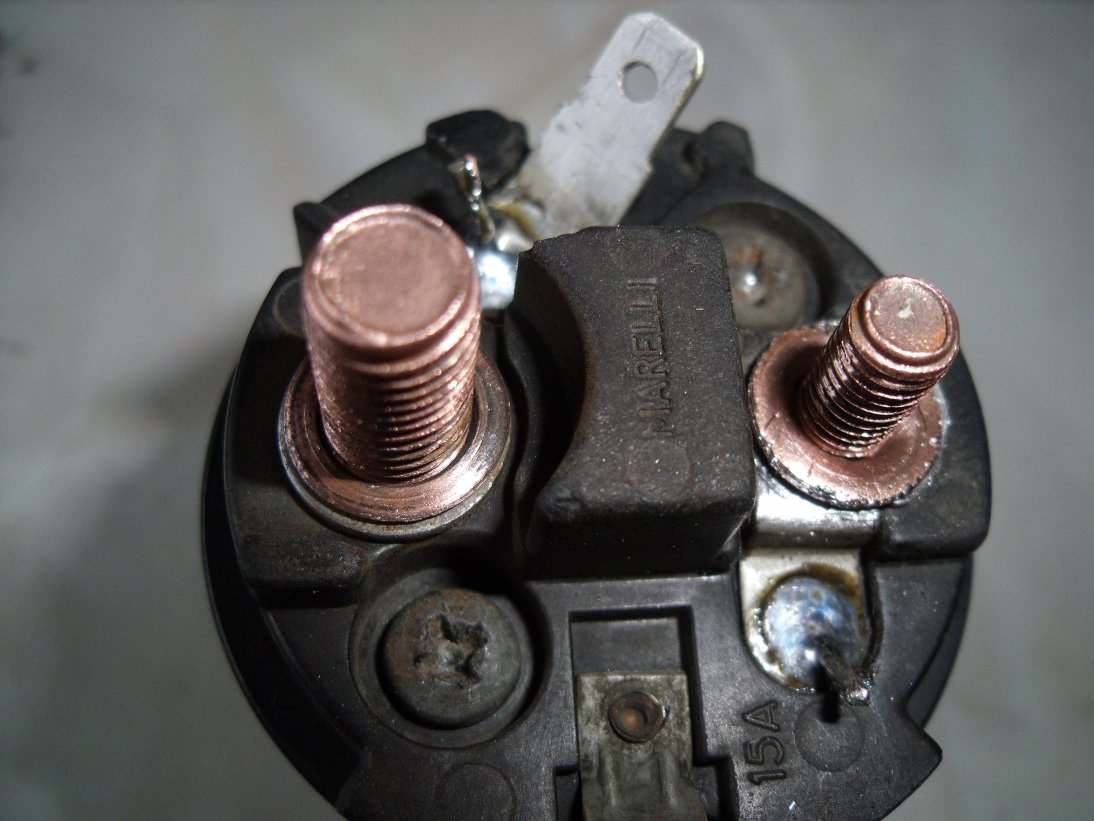

Essentially, what you have is a contact bar that projects into the bore of the solenoid. The bar is spring-loaded to maintain a gap between it and the two copper contact plates attached to the terminal threads:

When the windings are energised, the magnetic field created pulls the armature into the bore, which slides the Bendix gear into mesh with the engine's flywheel. Once meshed, the last bit of travel sees the armature hit the pin attached to the contact bar, forcing it backwards so that it shorts out the contact plates. This connects the battery to the starter motor. So it stands to reason that unless the contacting parts are in good shape and free from corrosion, oxidation and carbon caused by arcing, they won't transfer the necessary current to the motor (common cause of sluggish churning). I used a small file and a fibreglass pencil to brighten-up the relevant surfaces. You can see the pitting where the copper has been burned away over the years:

If you remove the copper washers it's possible to extract the threaded terminals if you need to :

Incidentally, the small copper terminal protruding from one side is the ballast resistor bypass; essentially it gets hit by the contact bar and supplies a 12v feed to the ignition system whilst cranking... but I'm sure you know the workings of a ballasted ignition, so we'll leave it there. On my unit the contact was actually loose and able to swivel, so I guess it made contact some of the time, meaning that on a ballasted-ignition car it'd be a source of problems!

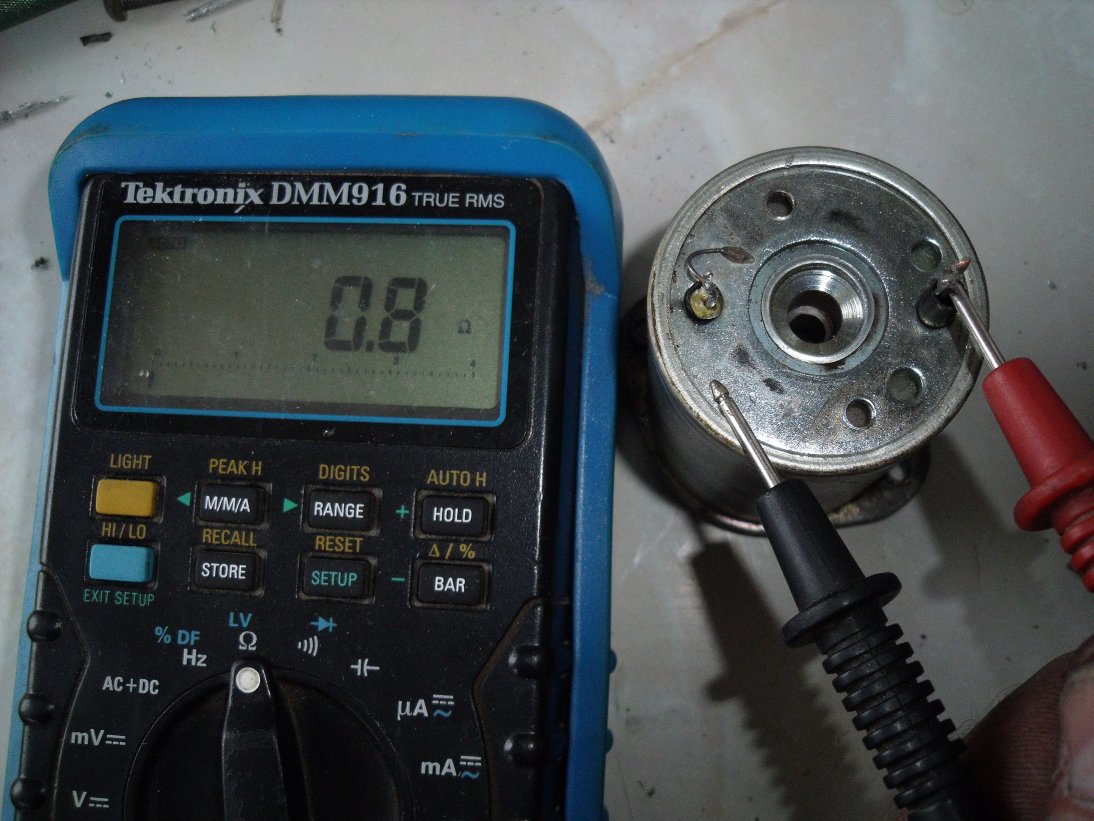

With all parts brightened-up and the bore cleaned out with iospropyl alcohol (it was a bit claggy, as I expected) I thought it'd be a good plan just to check that the copper windings were intact. There are two windings, a 'pull-in' winding and a 'holding' winding. The pull-in is energised by the cranking feed from the key and the holding winding gets fed once the contact bar is powering the motor. If you look closely you'll see that one of the soldered ends is actually two wires twisted together; this is one end of each winding. One end of one winding is earthed through the solenoid body, you can see it spot-welded here:

Use an Ohm-meter to check that the windings are intact; they will show a very low resistance:

Finally, drop the contact bar into the solenoid body, lower the end cap carefully into place so that the wire ends pass through the terminals (the twisted pair should be the cranking terminal - the large blade connector), press down against the spring and refit the screws. Resolder the terminals:

Before refitting the solenoid, I pulled the armature spring off and gave the armature a good wipe with IPA:

The various wires were re-attached (I cleaned the terminals on the battery and starter feed cables with emery cloth, although they were pretty clean anyway) - and the car has started fine, hot and cold, ever since! I even think the motor spins a bit faster now...